3T was established in 1990 and has grown into one of Europe’s major manufacturers of finned tube heat exchangers.

3T manufacture finned tube heat coils for many industrial or commercial applications such as:

- Petrochemical

- Process cooling

- Power Generation Cooling

- Marine

- Oil & Gas

- Hospitals

- Telecoms/Data Centres

- Food preparation and storage

- Leisure facilities

- Extract Booths

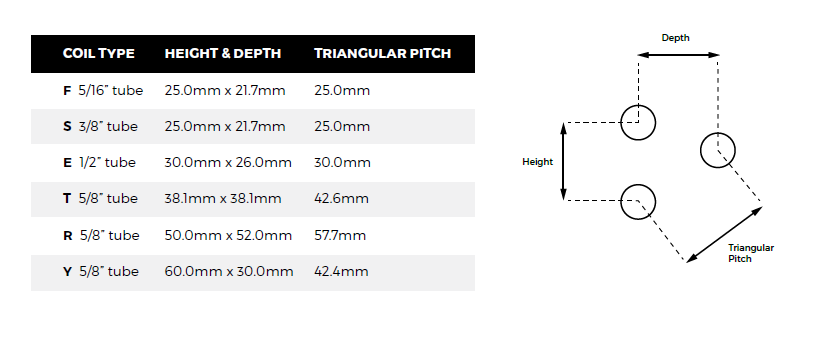

We manufacture a wide range of heat exchangers for various applications and media. As standard we can off in 5/16”, 3/8”, 1/2” or 5/8” tubes, both in close and wide tube configuration. As well as a number of different fin and tube materials to meet your project's requirements.

WE CAN OFFER

- Hot water air heating coils.

- Chilled water/liquid air cooling coils.

- Refrigerant condensing coils.

- Direct expansion refrigerant evaporator coils.

- Steam condensing air heating coils.

- Combined HW and CW coils.

- DX and CD heat-pump coils.

- Hot water air heating coils.

- Chilled water/liquid air cooling coils.

- Refrigerant condensing coils.

- Direct expansion refrigerant evaporator coils.

- Steam condensing air heating coils.

- Combined HW and CW coils.

- DX and CD heat-pump coils.

Our coils come in six different types of fin form in a range of materials:

Fin spacing or pitches are available between 1.6mm and 12.0mm depending on configuration and application. We carry sufficient levels of stock of the below materials to meet all our customers’ requirements:

Titanium Heat Exchangers

Titanium provides a long-term cost effective solution to heat exchange requirements in high saline level conditions. Fully Titanium coils allow the use of seawater as a coolant due to the metal's strong resistance to the corrosive properties of the fluid.

3T are one of only a handful of manufacturers worldwide that can produce fully Titanium (Fin and Tube) Heat Exchange Coils. As a specialist supplier, we have the capability to offer fully customised design of these coils to suit each individual projects requirements.

Benefits:

- Longer "working life" compared with alternative coil materials such as Cupronickel or Stainless Steel.

- Lighter weight of Titanium when compared to alternatives, crucial with applications such as offshore platforms.

- Over the lifetime of an offshore installation, maintenance requirements of a Titanium Coil will be well below those of units made from alternative materials. Thus reducing overall maintenance costs.

Features of our Titanium coils include;

- Grade 2 Titanium tubes (5/8" diameter)

- Various fin options: - Copper, Pre-tinned Copper, SS316, Grade 1 Titanium

- Fully Stainless Steel Casings and fixings

- Lightweight construction (around 20 - 30% lighter than the market norm.)

- Close configuration tubing allowing for a more compact coil.

- Lifespan ranging from 15 to 50 years dependent on specification and maintenance.

- Serviceable unit design allowing for internal cleaning of coil.

Dependant on the specification, we are able to offer lead times on titanium coils from as little as 4-5 weeks from order approval.

YOUR HEAT EXCHANGE PARTNER

Because we control the whole process, from procurement of raw materials through the design, manufacture of parts and final build of units we are able to fully customise our units to suit the exact needs of any particular project.